Thiot Ingénierie has provided its expertise in shock physics to qualify body armor. The development criteria for these protective items include reducing their weight while improving ballistic performance using high-performance materials. Here is how we proceed…

What is the role of each layer of body armors?

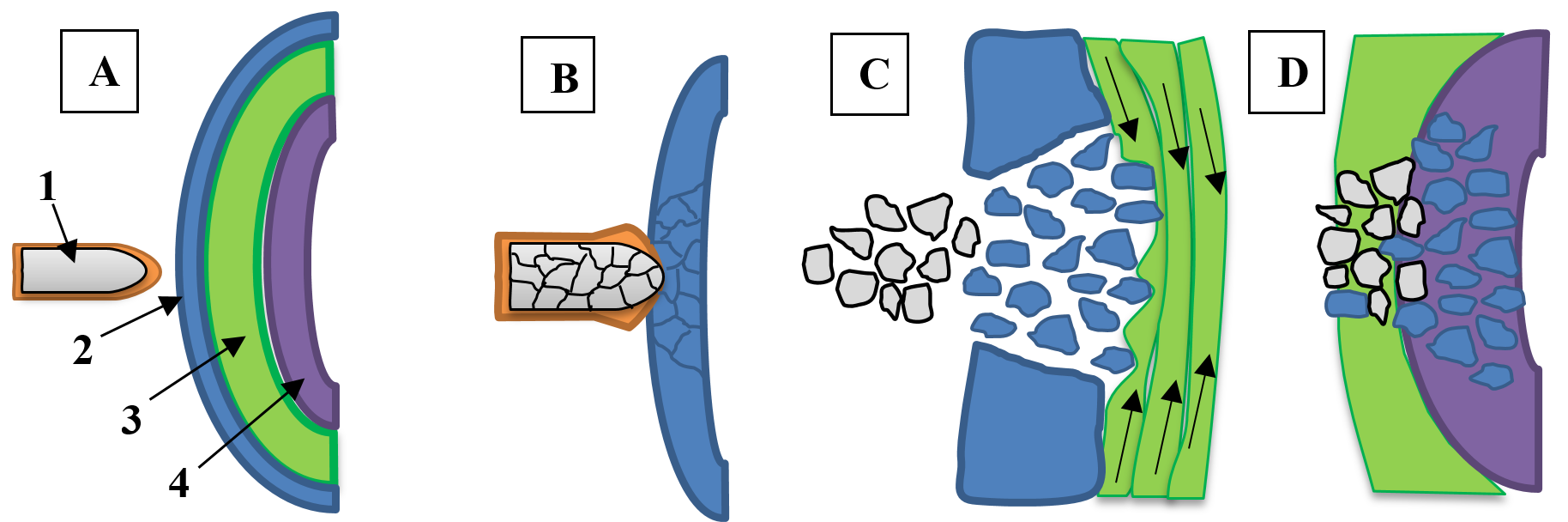

Typical body armor is made of three layers of complementary materials as shown in the diagram opposite. The first is generally a ceramic material (2) designed to fragment the projectile (1) [B]. The second is typically a composite material (3) that acts as a net to trap all of the debris (ceramic and projectile) [C]. The third layer is an anti-trauma foam (4) designed to soften the impulsion transmitted to the wearer’s chest [D].

Description of the methodology to characterize the behaviour of a body armor

Our team focused on characterizing the dynamic behavior of all of the components of this type of protection. The team conducted a combination of characterization tests and numerical simulations (using IMPETUS AFEA software) to calibrate material model for each material.

The characterization tests of each material were selected and scaled in accordance with the mechanical properties of each layer and the loading they have to withstand. Split-Hopkinson bars were used to identify the dynamic behavior both in compression and in shear while plate impact tests were carried out to identify the behavior under impact immediately following impact.

The test campaign terminated with ballistic tests using simple indenters (ball, cylinder) conducted individually on each material in order to refine the previously established material and failure models.

Lastly, validation tests were carried out with a 7.62 mm bullet in the characteristic ballistic range on a target created using a ceramic + composite layering. A final simulation confirmed the accurate reproduction of these validation tests.

This study is the perfect example of how an initiative combining both characterization tests and numerical simulation with adapted FEA software can reproduce the behavior of complete ballistic protections. This approach can be replicated at Thiot Ingénierie on all types of materials that are subjected to dynamic loadings.

subjected to threats of shock, impact, explosion?

Our team is at your side