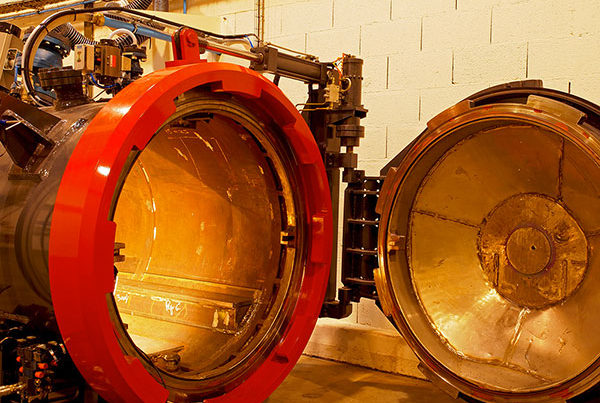

It has been almost 30 years since THIOT INGENIERIE started supplying the world’s leading research centres, universities and manufacturers with laboratory launchers and other facilities to study the behaviour of materials and structures of any type when subjected to shock stress. Our expertise in shock physics has since helped us develop a whole range of test equipment, including Split-Hopkinson bars, gas guns and powder guns, detonation chambers and acceleration generators. This list is not exhaustive: we are constantly innovating.

Shock physics was first studied by military research centres in the 1960s. Today, it also has many civilian applications in aeronautics, civil engineering, the aerospace sector and in shockwave metal forming.

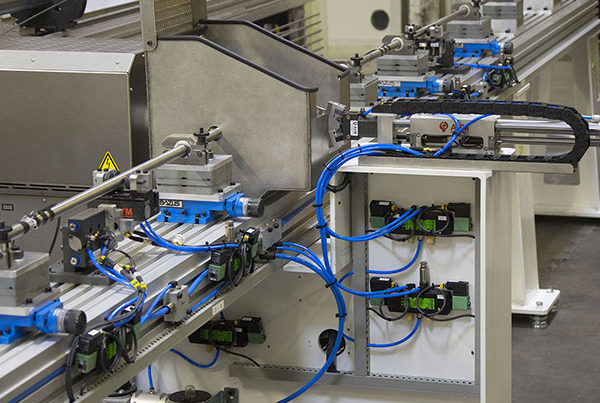

Our experts custom-design equipment in order to respond as best possible to the specifications of our clients and partners. Our products are easy to use and automated. They are designed to be equipped with the most sophisticated measuring instruments available on the market.