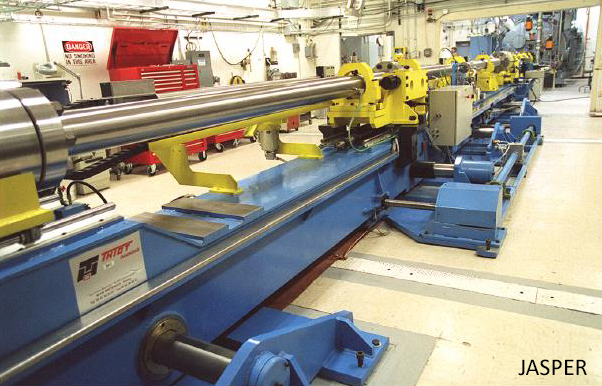

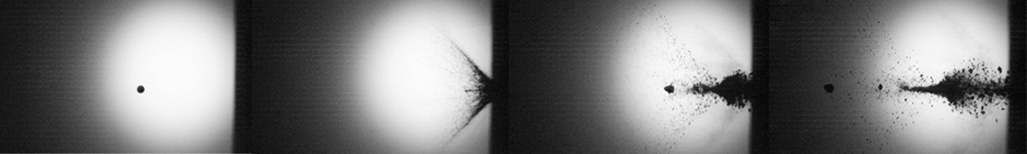

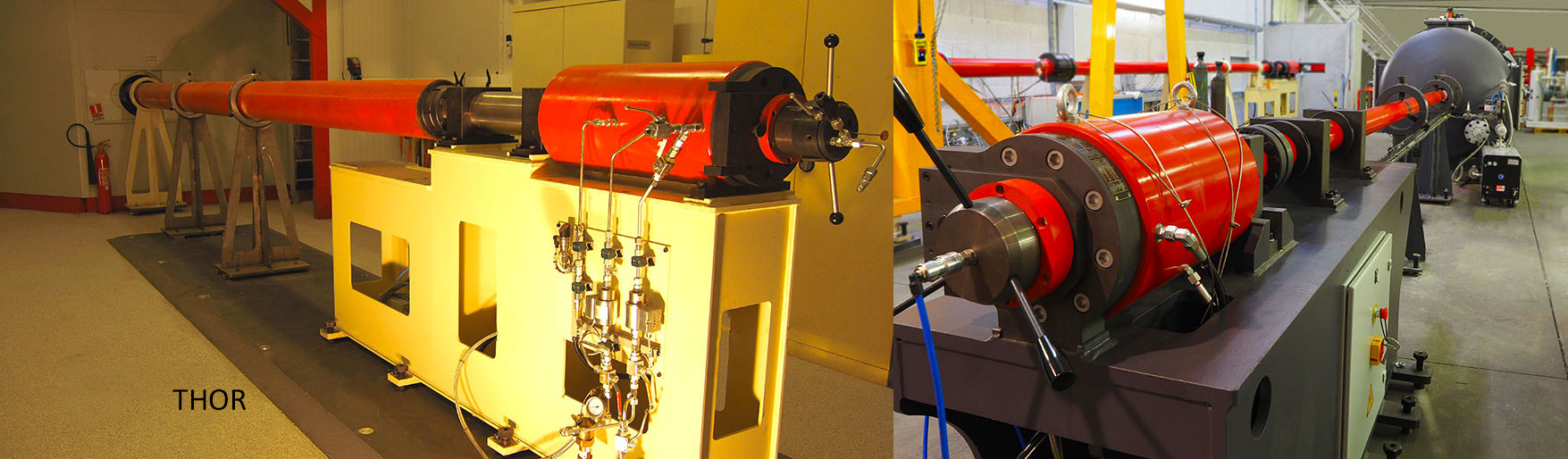

For thirty years, Thiot Ingenierie has been building and maintaining our reputation as a global leader. Our company uses initial expertise gained designing light-gas guns to develop a full range of test devices for laboratories and develop our own test laboratory combined with a numerical simulation center. Initially designers, over time we have become essential stakeholders in the knowledge of material behavior subject to fast dynamics for research and industry.

Looking back at our journey and development.