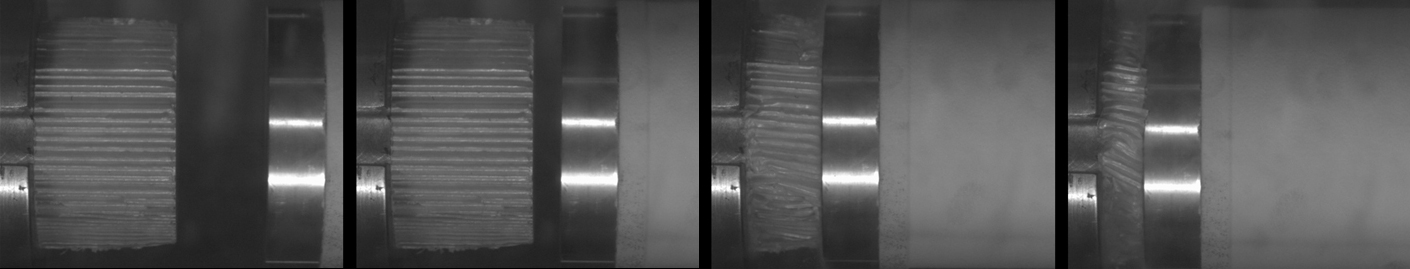

Dynamic material characterization involves studying and precisely evaluating the effects of high strain rates on the behaviour of materials. These tests are key in determining the properties of your materials, the mechanical behaviour of which can vary greatly depending on the strain rates to which they are subjected.

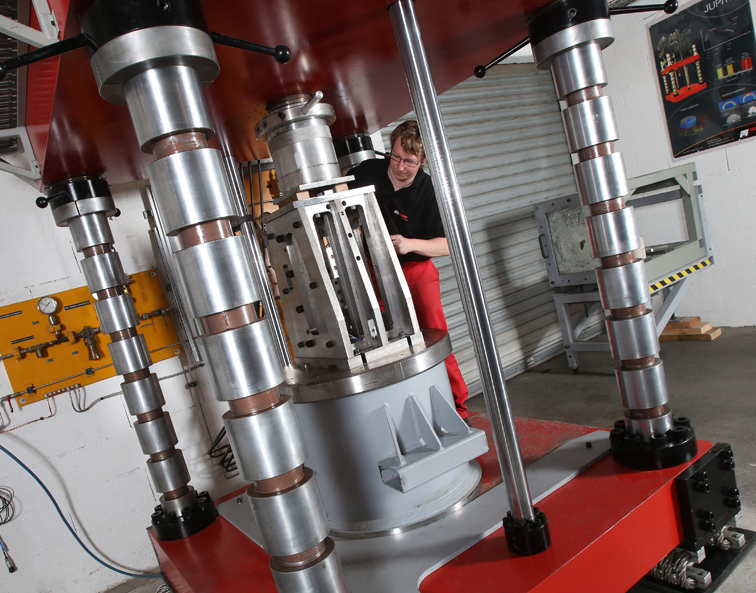

THIOT INGENIERIE offers you the winning formula. Our experts in fast dynamics conduct tests in our shock physics laboratory and use advanced numerical simulation techniques to provide you with a perfect understanding of how your materials and structures behave when subjected to shock stress and to guide you in the development of your products.