Our long-standing experience in the field of armament brought our laboratory into partnership with research centres and manufacturers in the defence industry in order to study impact phenomena on military structures (Army, Air Force and Navy) and to gain a better understanding of the behaviour and resistance of protective materials.

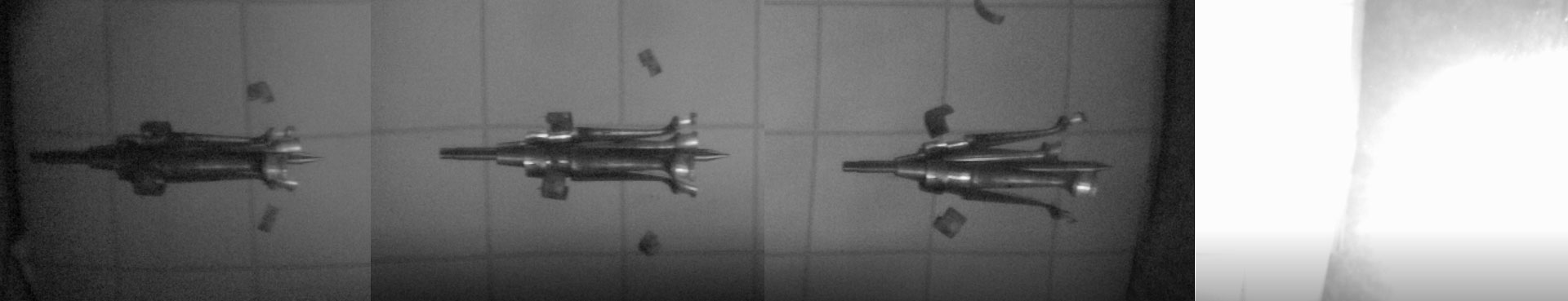

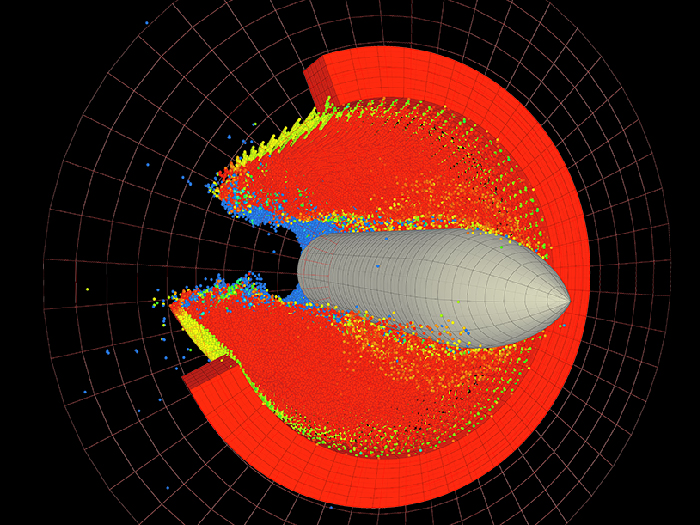

The wide choice of our test equipment meets all the requirements of our clients in the defence and security sectors: material characterization tests, ballistic tests, penetration tests with tungsten projectiles, acceleration tests for embedded systems in missiles, explosion, blast phenomena, etc.

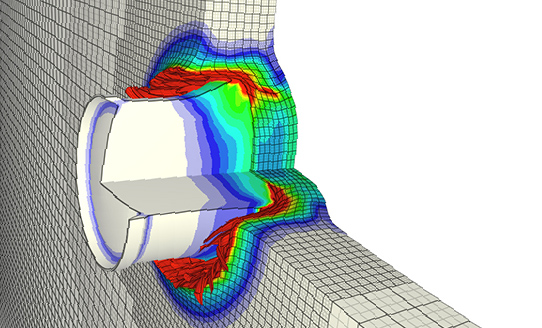

We combine laboratory testing and numerical computation. Our engineers and researchers provide you with support, according to your needs and at each stage in the development of your products, from the determination of the laws of behaviour of your materials to R&D expertise to improve your products and physical tests to validate the studies.