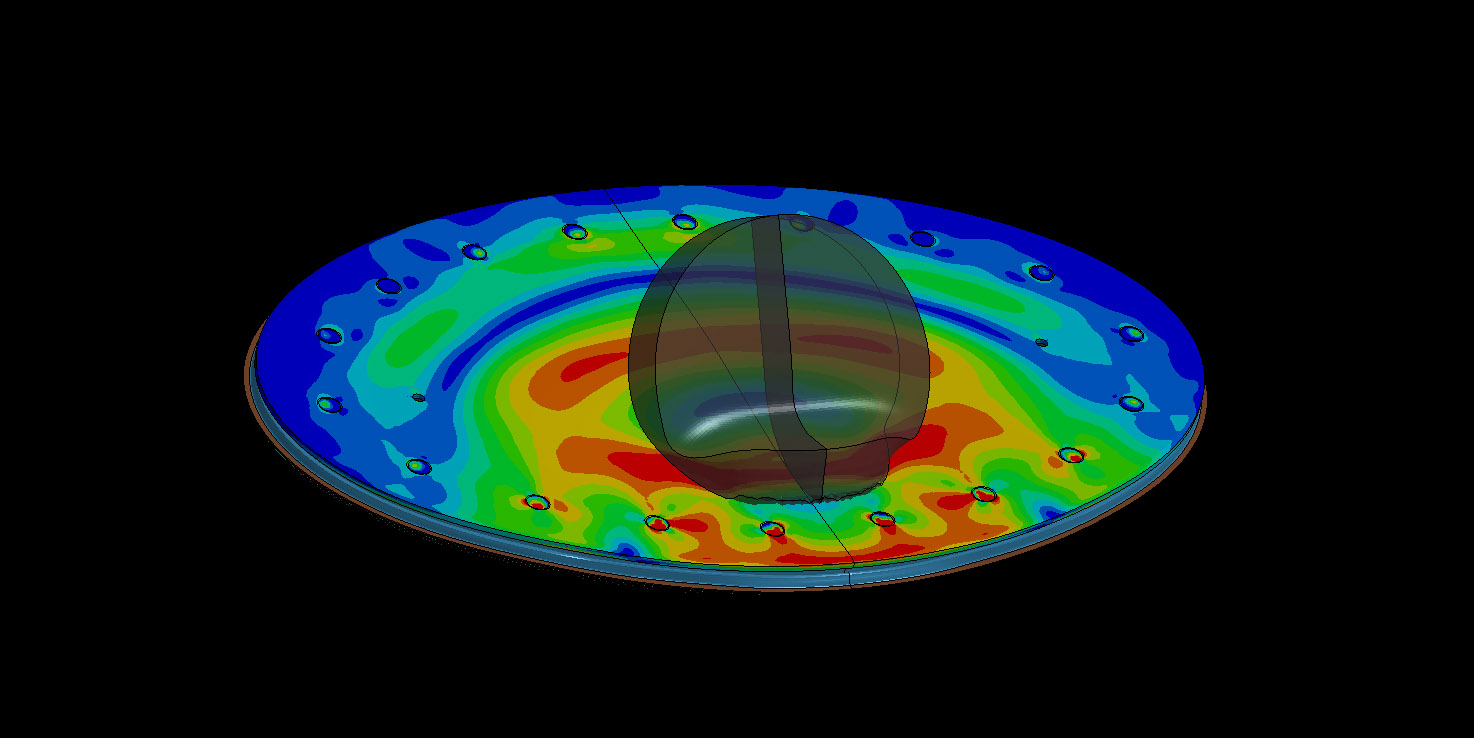

Aircraft, engine and equipment manufacturers need to be familiar with the behaviour models of their materials when these are subjected to high strain rates, improve the performance of their products and certify their structures to ensure that aircraft are safe and reliable. At THIOT INGENIERIE, our shock physics laboratory and our numerical simulation center work hand in hand to provide you with our global expertise and support you in your projects, from the design phase to the certification.

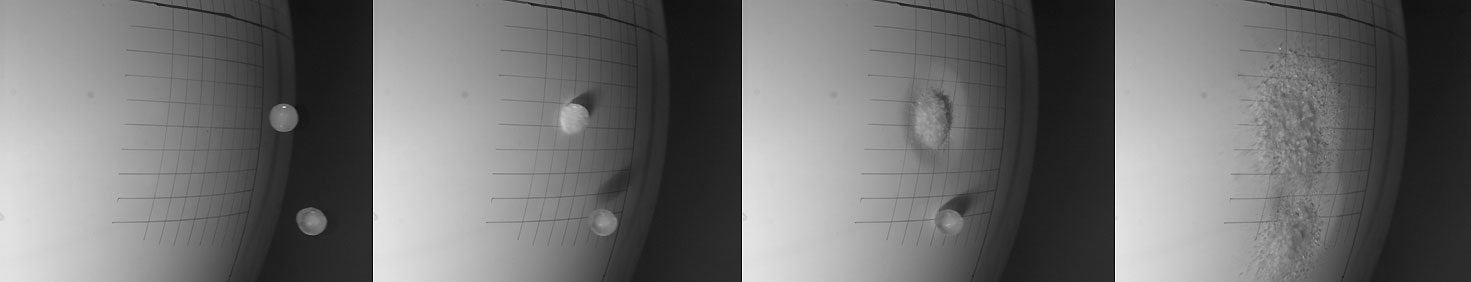

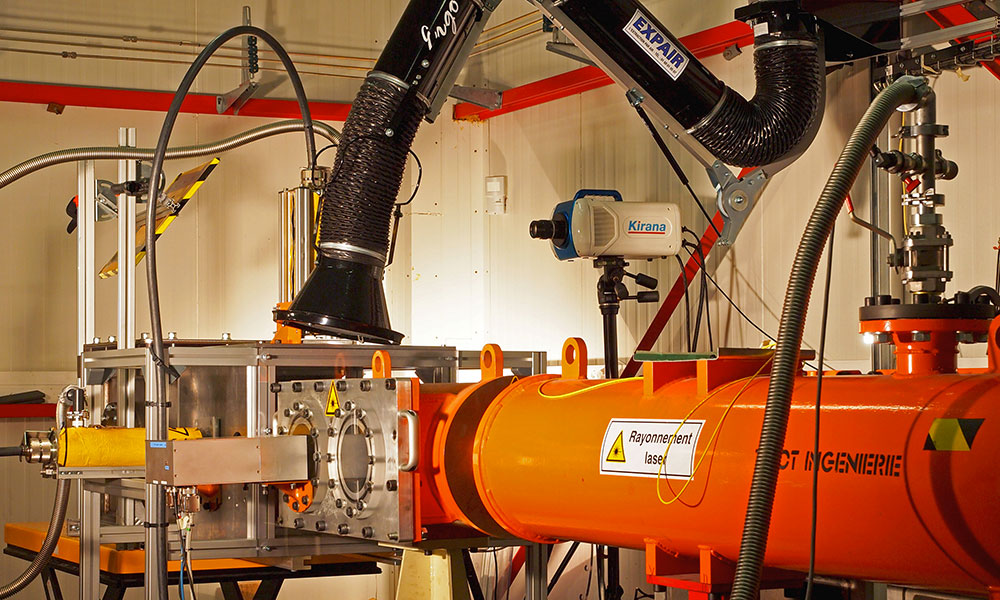

Using our laboratory launchers (velocities of up to 1200 m/s for the aeronautics sector) equipped with barrels with a calibre of up to 350 mm and our firing-range chambers with metrology tools, we are able to perform impact tests using any type of projectile that poses a threat to aircraft—hailstones, blocks of ice, stones, bird strikes, pieces of tire, propeller and turbine blades—and on any type of structure (windscreen, radome, turbine blade, etc.).