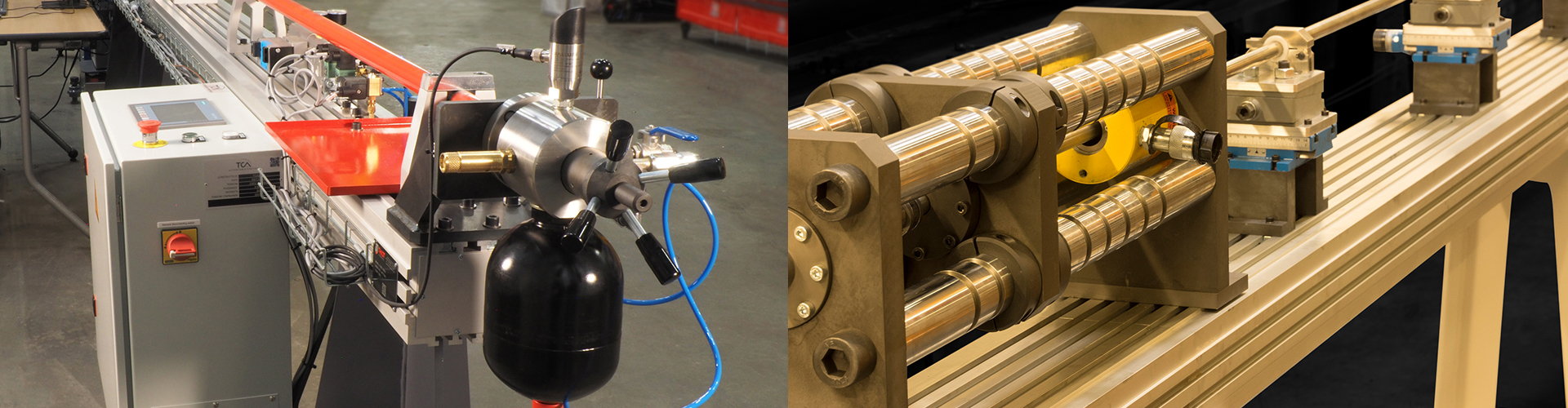

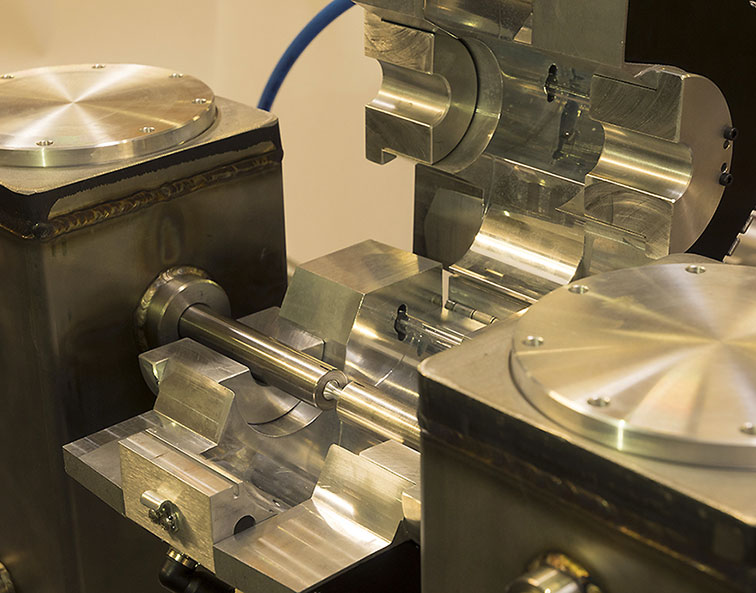

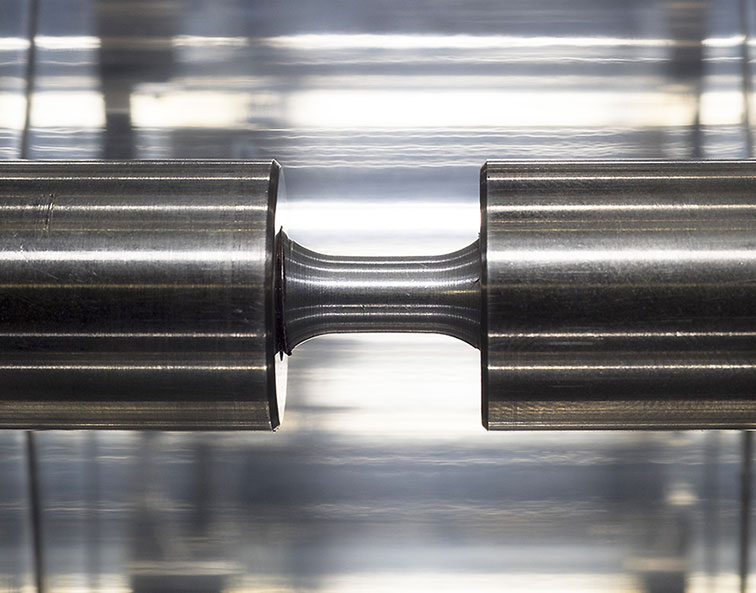

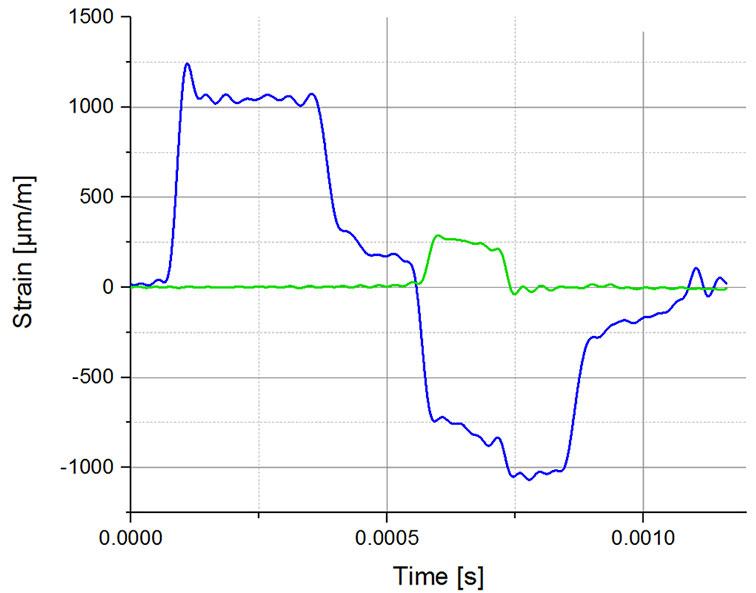

The Split-Hopkinson bars we manufacture are the best test equipment for characterizing the dynamic behaviour of materials subjected to high strain rates at a given temperature (-150°C to +800°C), by means of either compression or tensile testing. At THIOT INGENIERIE, we design compression bars that are unequalled on the market, as well as direct tensile-test bars with a revolutionary operating principle.

Our Hopkinson bars are intended for use by research centres, universities and manufacturers from a wide variety of sectors (aeronautics, defence, automotive industry etc.). These testing systems allow tests to be performed on all types of material samples, e.g. aluminium, composites, titanium, ceramic, foam, 3D-printing materials, plastics and polymers. Our aim: provide you with the most accurate data possible.