At THIOT INGENIERIE, we deploy our expertise for innovative projects, especially those pertaining to space exploration. Since the 1970s, several projects were rolled out to further our knowledge of the surface of Mars and they are still key priorities in the study of the red planet today. NASA and ESA have therefore set themselves the goal of sending a space capsule to planet Mars within the next few decades to collect samples from its surface and bring them safely to Earth in a crash-proof container.

ESA chose MECANO-ID to develop and design a capsule, initially intended for the Mars exploration missions MSR and PHOOTPRINT. In turn, MECANO-ID called upon THIOT INGENIERIE to assist with this exceptional project. Our mission was to select a material able to withstand the mechanical and thermal shock that the capsule will undergo when it crashes back down to Earth, and thus ensure that the bio-container inside it remains intact to protect its precious samples.

The extreme conditions facing the capsule upon its return to Earth

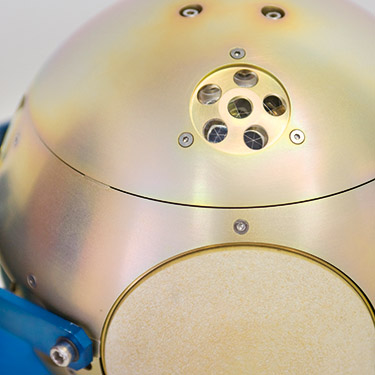

After the surface samples have been collected on Mars, the capsule containing the bio-container will crash back down to Earth, without a parachute, at a speed of 40 m/s. The challenge lies in ensuring that it will mechanically withstand the crash (not exceeding a maximum rate of acceleration) while preserving the samples, even in the event of an accident, and in ensuring that the bio-container holding them remains sealed so as to avoid any biological risk. Another factor to consider is that the capsule’s landing site could turn out to be in either a temperate or tropical region. The samples would have to be kept below a certain temperature until the capsule is recovered.

picture from MECANO-ID website

How were the materials selected?

THIOT INGENIERIE was tasked with identifying materials that would be suitable for such a project. Various criteria were taken into account in order to find the most appropriate material for returning the samples in the necessary conditions. These included mechanical and technical criteria as well as criteria concerning compatibility with the environment in space.

The ability of foams to absorb thermal and mechanical shocks in response to ballistic impacts, collisions and explosions has been established for decades in the automotive, defence and aerospace industries. Other materials developed to absorb shocks also made for good candidates.

Dynamic characterisation: materials under crash-test conditions

Several types of material were thus selected and then tested in order to ascertain their dynamic behaviour.

- PMI (polymethacrylimide) polymer foam: a commonly used material with isotropic behaviour (mechanical properties identical in all directions). Can be satisfactorily shaped, but thermal resistance is borderline

- RVC (Reticulated Vitreous Carbon) metal foam: highly technical material with isotropic behaviour, excellent thermal insulating properties, but more complicated to procure and machine

- Structured materials like honeycomb composites: exceptional thermomechanical properties. Not widely used. Orthotropic behaviour (mechanical strength depends on the direction of stress)

The characterisation tests involved impacting the material with non-deformable projectiles of various shapes and at speeds close to those involved in the application. High-speed videos were filmed, and the load transmitted by the material was recorded. All the data were analysed and then our team, in partnership with MECANO-ID, was able to provide ESA with a ranking of the different materials.

Full-scale prototype crash test

Following the study of the laws of behaviour for each of the materials used, ESA selected the material to be used by MECANO-ID for this study. It was decided to carry out a full-scale impact test, for which MECANO-ID designed a prototype resembling the final design as closely as possible, while fulfilling the test conditions achievable in our laboratory. We therefore crash tested this capsule on a rigid wall, with a high-speed video recording and continuous measurement of the bio-container’s deceleration using embedded accelerometers.

The capsule was recovered intact, its final geometry and post-test damage were examined and all of the recorded signals were analysed, enabling MECANO-ID to substantiate its study and present it to ESA for both of the missions envisaged.